This study was aimed to determine and compare the chemical and microbiological properties of yoghurts made from different types of milk and their mixtures (35%, 65%, and 100%) during their storage at 4 °C for 28 days. For this purpose, chemical and microbiological properties of yoghurts during storage at 4 °C for 28 days were investigated. The total amount of dry matter, fat, pH and protein of yoghurt made from the buffalo and cow milk mixtures was significantly higher than that of pure buffalo milk (P<0.01). Also, storage time has led to significant differences in these components. Considering the results of microbiological analysis, a significant (P<0.01) difference was found between yoghurt samples in terms of total count of mesophilic aerobic bacteria, lactobacilli, lactococcus and yeast and mould. Hence, it is concluded that the addition of buffalo milk to that of cow improves the composition of yoghurt made from cow milk, which indicated the possibilities of processing and marketing of both types of milk especially because the health benefits of cow milk and the fermented products are well documented. ALAN, 2019; 69(2): 89-98.

Key words: Buffalo milk, cow milk, starter culture, yoghurt, chemical and microbial composition.

El objetivo de este estudio fue determinar y comparar las propiedades químicas y microbiológicas de los yogures hechos con diferentes tipos de leche y sus mezclas (35%, 65% y 100%) durante su almacenamiento a 4° C por 28 días. La cantidad total de materia seca, grasa, pH y proteínas del yogur hecho con las mezclas de leche de búfala y vaca fue significativamente mayor que la de la leche de búfala pura (P <0.01). Además, el tiempo de almacenamiento generó diferencias significativas en estos componentes. De acuerdo con los resultados del análisis microbiológico, se encontró una diferencia significativa (P<0.01) entre las muestras de yogur en términos de bacterias mesófilas aerobias totales, lactobacilos, lactococcus y recuentos totales de levadura y mohos. Por lo tanto, se concluye que la adición de leche de búfala a la de vaca mejora la composición del yogur hecho de leche de vaca, lo que indica las posibilidades de procesamiento y comercialización de ambos tipos de leche, especialmente porque los beneficios para la salud de la leche de vaca y de los productos fermentados están bien documentados. ALAN, 2019; 69(2): 89-98.

Palabras clave: Leche de búfalo, leche de vaca, cultivos iniciadores, yogur, composición química y microbiana.

https://doi.org/10.37527/2019.69.2.003

Autor para la correspondencia: Asya Çeti̇nkaya, email: [email protected]

Yoghurt is a primary dairy product with high nutritional value and digestibility. In addition to the high biological value of their proteins its digestibility is twice as high as compared to milk (1). Lactic acid provides nutritional value and physiological advantages in yoghurt and facilitates the use of calcium, phosphorus, and iron (2). Due to partial protein hydrolysis, fat and lactose content during fermentation, yoghurt is easy to digest. Suitable for people with lactose intolerance, yoghurt also has antitumor and anticholesterolemic properties. Antibiotics and antimicrobial agents produced by lactic acid bacteria protect humans against pathogenic microorganisms. For these reasons, yoghurt is a cheap fermented dairy product that can be used in the daily nutrition of people of all ages (3).

According to the TS 1330 Yoghurt Standard of the Turkish Standards Institute, yoghurt is obtained by pasteurizing cow milk (TS 1018), sheep milk (TS 11044), buffalo milk (TS11045), goat milk (TS 11046) or mixtures thereof, or by homogenizing pasteurized milk (TS1019) with the addition of milk powder if necessary (TSE 1329) or with the addition of yoghurt culture consisting of Lactobacillus delbrueckii subsp. bulgaricus and Streptococcus thermophilus after the procedures in accordance with TS 10935-Yoghurt Making Rules Standard (4).

According to the 2016 Turkish Statistical Institute the production of yoghurt is 994.006 tons/year. There are 142.073 buffalos in Turkey and 63.029 tons/year milk are obtained from them. Buffalo milk amounts to approximately 0.34% of total milk production (5). Because buffalo milk production requires certain climatic and geographical conditions and milk yield is low and seasonal compared to cow milk, buffalo's milk is a rare type of milk.

With its rich composition, nutritional value and distinctive taste and aroma, buffalo milk differs from other types of milk. Besides, the high dry matter and fat content and the size of the fat globules increase the importance of buffalo milk regarding technology (6). Buffalo milk contains more dry matter and has a higher vitamin A, calcium and phosphorus content than cow milk. Also, its colour is whiter. Its high protein content increases the yield in cheese production. Serum proteins from buffalo milk proteins have higher resistance to heat than cow milk proteins. These characteristics cause an increase in the resistance of buffalo milk and its products against heat treatment (7).

With its composition and aroma, buffalo milk is useful in the formation of the characteristic organoleptic properties of some dairy products. Buffalo milk is superior to cow milk, regarding not only its flavour but also its nourishing properties such as 58% more calcium, 40% more protein, and less cholesterol (8). It has been reported that the amount of tocopherol in buffalo milk and the peroxidase activity is 2-4 times higher than in cow milk (7, 8). The presence of various bioprotective agents such as immunoglobulins, lactoferrin, lysozyme, and lactoperoxidase in buffalo milk makes buffalo milk superior for special diets and healthy food. Excess fat content and dry matter increase the yield in creams, butter, and milk powder (7). Due to the intense aroma of buffalo milk, it is not preferably consumed as drinking milk. It is used in yoghurt production due to the high fat and dry matter content. Also, the large fat globules make it easy to churn, so it is often used as a raw material in cream and butter production. Studies have reported that the nutritive value of yoghurt made from buffalo milk, which is richer in protein, carbohydrate, fat and mineral matter is higher than those made with cow milk or other types of milk. Furthermore, it has been found that yoghurt made from buffalo milk is more viscous and aromatic and contains more protein, fat, phosphorus and calcium and is more easily digested (8).

Taking these as a starting point, this study aims to determine the properties of yoghurts obtained from buffalo milk and buffalo and cow milk mixtures during the storage and to contribute to the widespread use of buffalo milk in yoghurt production.

Cow milk was obtained from milk producers in the city of Kars/TURKEY while the buffalo milk was obtained from different producers in the city of Iğdır/TURKEY. The YC-350 (Streptococcus thermophilus and Lactobacillus delbrueckii subsp. bulgaricus) culture came from Chr Hansen-Peyma. As yoghurt containers, 400 ml glass jars were used. Yoghurt samples were stored at 4±1 °C and analysed on days 1, 7, 15 21 and 28.

Yoghurt production was carried out in the Research Laboratory of the Department of Food Engineering of Kafkas University, according to the method proposed by Atamer et al. (1988)(9) Yogurt batches were produced by triplicate (Figure 1).

Total solids, fat and ash were determined by standard procedures (10). Protein content was determined according to Kjeldahl method (11), Water holding capacity (12) of milks and yoghurt samples were also determined. The pH was measured with a pH meter (model WTW, Weilheim, Germany).

Synaeresis value was determined by volumetric measurement of the amount of serum separated after filtering 25 g yoghurt sample at 20±1 °C for 2 hours through a filter paper (porous size 25μm) (13).

10 g of yoghurt samples were homogenized with Vortex (Model: 58816-123, VWR, USA) with 90 ml sterile ringer solution. After homogenization, yoghurt was diluted at 1/10 with sterile ringer solution, and serial dilutions were prepared. The samples were examined regarding total mesophilic aerobic bacterial and Lactobacillus, Lactococcus, yeast, and mold.

Yoghurt samples were kept in Plate Count Agar (PCA) for 48 hours at 48 °C for the total mesophilic aerobic bacterial count, in M 17 agar (Merck) for 72 hours at 37 °C for the lactococci count, in Man Rogasa Sharp (MRS) agar (Merck) for 72 hours at 37 °C in an anaerobic environment for the lactobacilli count, and in Potato Dextrose Agar (PDA) for 4-5 days at 25 °C for the yeast and mold count (14).

Data obtained from this study were evaluated with SPSS 18.0.0 package program using variance analysis (two-way ANOVA). The differences between the mean values were compared with the Duncan's Multiple Range.

Tables 1-11 present the results of chemical and microbiological analyses of yoghurt samples made from buffalo and cow milk and their mixtures and their changes during storage.

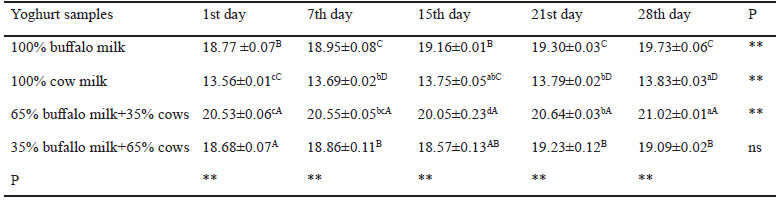

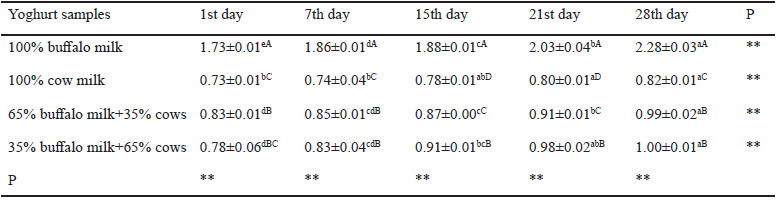

Table 1 presents the total solids of yoghurts made from buffalo milk, cow milk and buffalo and cow milk mixtures during the storage period. The results indicate that the total solids of yoghurt made from buffalo milk and cow milk increased. Higher total solids levels were observed in the yoghurt samples made from 35 % cow milk + 65 % buffalo milk. Yoghurt samples showed significant (P <0.01) differences during the storage period.

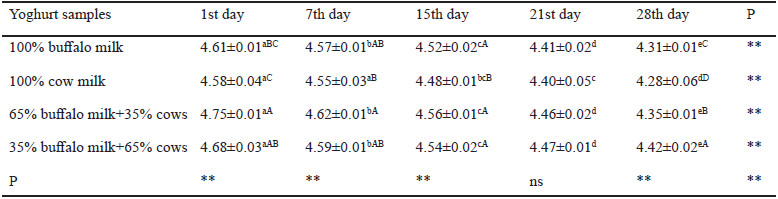

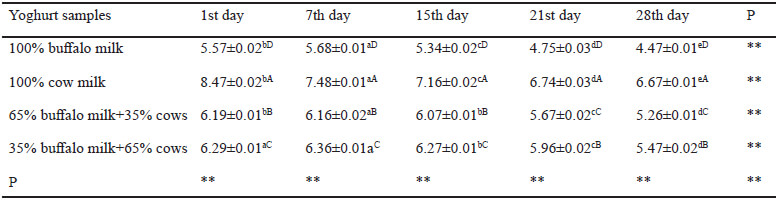

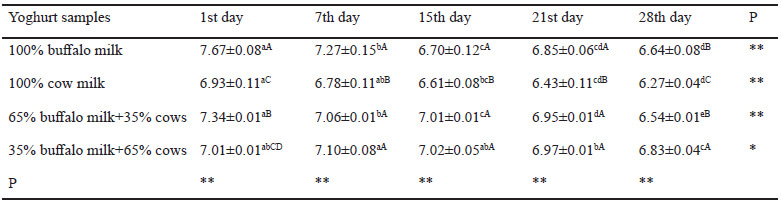

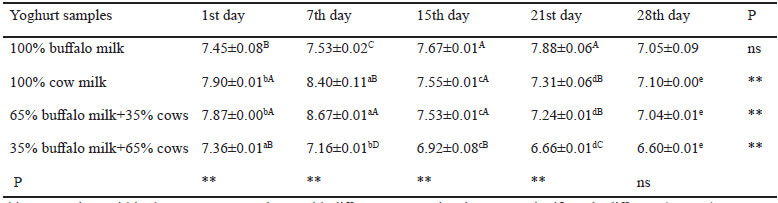

The pH content of the yoghurt samples obtained from buffalo, cow and buffalo + cow milk mixture is shown in Table 2. The pH values of all yoghurt groups decreased during storage. This is due to the ongoing bacterial activity, even at low storage temperatures. During the storage period, significant (P <0.01) difference was determined between yoghurt samples.

A significant (P <0.01) difference was found between yogurt samples during storage except for 21 days. It is thought that the differences in the pH value may be due to the differences in the materials used in production as well as the strain differences of the starter cultures used in the production of yoghurt, the incubation temperature and time applied in the production, the shelf life of the product and the storage conditions.

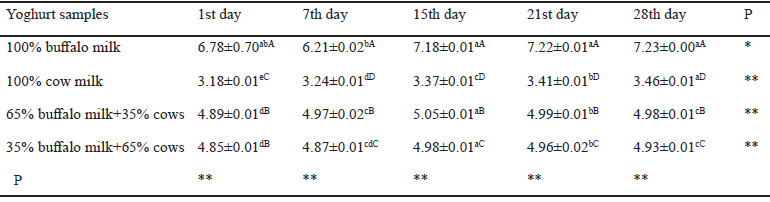

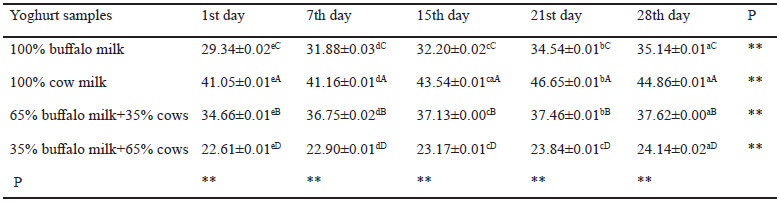

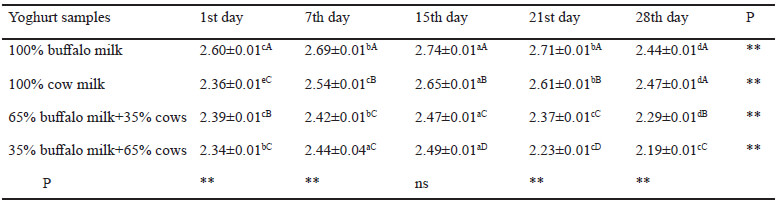

The protein content of yoghurt made from buffalo and buffalo and cow milk mixtures is shown in Table 3.

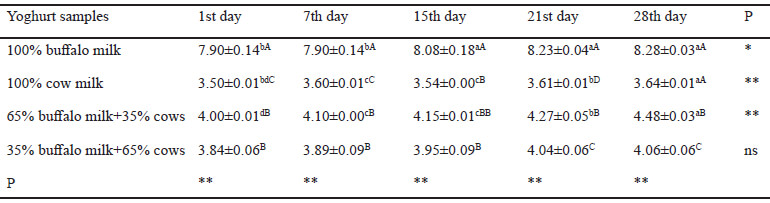

The fat content of yoghurt made from buffalo milk and buffalo and cow milk mixture is shown in Table 4. Significant difference was determined between yoghurt samples (P <0.01). A higher fat content was found in yoghurt samples made from 65% buffalo milk + 35% cow milk.

Ash contents of the yoghurt samples obtained from Buffalo and buffalo + cow milk mixture are shown in Table 5. Significant difference was determined between yoghurt samples (P <0.01).

Serum contents of the yoghurt samples obtained from Buffalo and buffalo + cow milk mixture are shown in Table 6. The highest serum amount was determined in yoghurt made from cow milk. Significant (P<0.01) differences were determined among the yoghurt samples during storage.

Significant difference (P <0.01) was determined among the yoghurt samples, and the highest water-holding capacity was determined in the yoghurt made from cow milk.(Table 7)

Dry matter contents of the yoghurt samples made from buffalo milk were higher than those reported by Erkaya and Sengül (15), Ismail et al. (16), Bilgin and Kaptan (17), and El Tahra et al. (18), similar to those of the yoghurt made from buffalo milk in the study by Ergöz (6).

The amount of protein has a great influence on the nutritive value and structure of the yogurt. In yogurt made from milk with high protein content, viscosity increases, and synaeresis decreases (Herdem, 2006). The protein value of the yoghurt samples was higher than the values reported by Erkaya and Sengul (15), similar to the values reported by Bilgin and Kaptan (17). pH values of the yoghurt samples made from buffalo milk were similar to those reported by Ismail et al. (16) and El Tahra et al. (18).

The fat content of the yoghurt samples was lower than those reported by Erkaya and Sengul (15), but higher than the yoghurt samples made from buffalo milk in the studies by Ergöz (6) and Ismail et al. (16), and Bilgin and Kaptan (17). Ash content of the yoghurt samples was higher than that of the yoghurt samples made from buffalo milk in the studies by Bilgin and Kaptan (17) and El Tahra et al. (18).

Serum content of the yoghurt samples (4.47-5.68 mL/25g) was higher than that of the yoghurt samples made from buffalo milk in the study by Erkaya and Sengül (15).

The water-holding capacity of the yoghurt samples was determined between 35.87% and 37.11%. This value is lower than the values reported by Ipin (19) in cream yoghurt.

Dry matter, protein, pH, ash and fat values of the yoghurt samples made from cow milk were 13.56-13.83%, 3.28-3.45%, 4.28-4.58, 0.71-0.82%, 3.55-3.63%, respectively. Dry matter content was higher than that reported by Erkaya and Sengül (15) similar to that reported by Eren-Karahan (20).

Protein values of yoghurt samples were similar to those reported by Bakırcı et al. (21) and Erkaya and Sengül (15).

The fat contents were similar to those reported by Ismail et al. (16) and Erkaya and Sengül (15) lower than those reported by Eren-Karahan (20) higher than those reported by Bakırcı et al. (21). The ash contents were higher than those reported by Erkaya and Sengül (15), but lower than those reported by Ismail et al. (16).

Serum contents of the yoghurt samples were higher than those reported by Bakırcı et al. (21), and in the range of the values reported by Atamer and Sezgin (13).

Water-holding capacities of the yogurt samples were lower than those reported by Felipe et al. (22).

The dry matter and fat content of yogurts made from buffalo and cow milk increased during storage. This was also reported in studies conducted by other researchers (18). Dry matter and protein contents of the yoghurt samples made from buffalo and cow milk mixtures were higher than those of the yoghurt samples made from buffalo and cow milk mixtures (1: 1) in the study by El Tahra et al. (18) and from cow + sheep milk mixtures in the study by Felipe et al. (22).

Fat amounts of the yoghurt samples were higher than those of the yoghurt samples made from buffalo + soy milk + cow milk mixture in the study by Ismail et al. (16), from buffalo + cow milk mixture in the study by Petridis et al. (23), from sheep + cow milk mixture in the study by Felipe et al. (22), and from camel milk + cow milk mixture in the study by Ibrahem and El Zubeir (24).

pH values of the yoghurt made from buffalo + cow milk mixture in different proportions were similar to those of the yoghurt samples made from buffalo + soy milk + cow milk mixture in the study by Ismail et al. (16), and from buffalo + cow milk mixture (1: 1) in the study by El Tahra et al. (18).

Ash contents were higher than those reported by Felipe et al. (22).

TAMB content of the yoghurt samples made from buffalo and buffalo + cow milk mixture is shown in Table 8. During the storage period, significant (P <0.01) difference was determined between yoghurt samples.

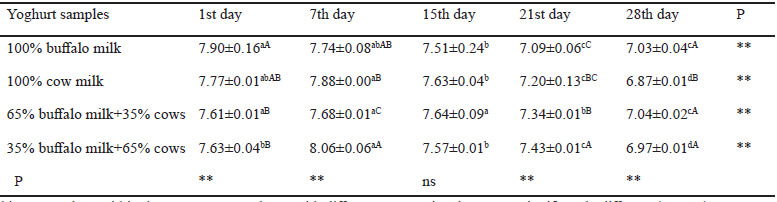

The changes in the Lactobacilli and Lactococcus bacterial counts of the yoghurt samples obtained from buffalo, cow, and buffalo + cow milk mixture are given in Table 9. A significant (P <0.01) difference was found between yoghurt samples during storage except 28 days for Lactobacilli and 15 days for Lactococcus.

Significant difference (P <0.01) was found between yoghurt samples made from buffalo milk and 65% buffalo milk + 35% cow milk; an insignificant difference was found between yoghurt samples made from cow milk and 65% cow milk + 35% buffalo milk. The effect of storage time on the yeast-mold count (P <0.01) was found to be significant except 15 days for yeast-mold.

Total aerobic mesophilic bacteria are hygiene indicator microorganisms. Total aerobic mesophilic bacteria can provide information about the possible shelf life of food and contamination levels in the production stages.

Total count of aerobic mesophilic bacteria in the yoghurt samples made from buffalo milk and cow milk mixtures was lower than that reported by Ertas et al. (8) and Bilgin and Kaptan (17). Lactobacillus bacterial count of the yoghurt samples were similar to that of the yoghurt samples reported by Bilgin and Kaptan (17) in the yoghurt samples made in home conditions and small dairy farms. Moreover, it was found to be higher than that of the yoghurt samples reported by Ertaş et al. (8) in the buffalo yoghurt sold in Kayseri.

Lactococcus bacterial count was higher than that of the yoghurt samples reported by Bilgin and Kaptan (17) in the yoghurt samples made in home conditions and small dairy farms. (Table 10)

Yeast-mold count in the yoghurt samples during storage was lower than that reported by Ertas et al. (8) and Bakırcı et al. (21), lower than that reported by Bilgin and Kaptan (17) in the yogurt samples made in home conditions, but was in the range of the values obtained in the yoghurt samples made in small dairy farms. (Table 11)

It is stated in the Turkish Food Codex Yoghurt Notification that the total count of specific microorganisms must be at least 107 (CFU/g) and the count of yeast-mold should be 102-103 CFU/g. TAMB and yeast-mold counts determined in the yoghurt samples are in the specified range (25).

The results of the yogurt samples differ from the results of other researchers. Factors such as type, composition, production period of milk, production methods of yogurt, storage period and packaging material are effective in the formation of these differences. The microorganism load of the milk, the excessive initial microbial load, the inadequate heat treatment applications, no standard production method, the insufficiency of equipment and personal hygiene may be determining factors in the differences observed in terms of microbiological evaluation.

In this study, yogurt samples made from buffalo milk determined dry matter, fat, protein ratios were higher than other researchers' values. In addition, the dry matter, fat, protein content of yogurt samples made from buffalo cow's milk mixtures (65% buffalo milk + 35% cows) were found to be higher than those determined by yoghurts made by buffalo + cow and other milk mixtures. The differences in total dry matter, fat and protein ratios are thought to be due to differences in the composition of milk processed in yoghurt and the techniques used in yoghurt production.

It was observed that the addition of different amounts of buffalo milk improved the chemical composition of yoghurt during the storage period. This is due to the higher fat content and the total solid content of buffalo milk. These differences between buffalo and cow milk compositions can affect the processing characteristics of dairy products and facilitate coagulation in milk-based products, along with faster coagulation. This allows the production of more viscous and tighter yoghurt. For these reasons, we believe that the addition of buffalo milk in yoghurt production will increase yoghurt quality and buffalo milk will be an excellent raw material for processing different dairy products.

Asya Çetinkaya: https://orcid.org/0000-0002-6189-7929

Recibido: 25/01/2019

Aceptado: 12/08/2019