In this study, the effect of processing and storage time on the vitamin C and lycopene contents was evaluated. Guavas were washed, cut in quarters, blanched, pulped and the pulp pasteurized. The pulp was used for the production of nectar: guava pulp, sugar and water were mixed in 5:3:12 proportions, and the mixture was pasteurized, poured while hot into 125 mL glass jars, and cooled rapidly to 25°C. The production of nectar from fresh guava reduced vitamin C, lycopene and titratable acidity, by contrast soluble solid and pH increased significant. Vitamin C content from 168.9 to 62.3 mg/(100 g fresh weight), and lycopene content from 3.55 to 1.35 mg/(100 g fresh weight) (p < 0.001 in both cases. After 240 days at 10.0 ± 2°C, no further statistically significant change in lycopene and soluble solid content was observed (p > 0.05). Storage time did affect vitamin C, pH, and titratable acidity content, vitamin C content fell by 89.3% to 6.67 mg/(100 g fresh weight) (p < 0.001). Based on this study, guava nectar storage at 10 ° C retained 46% of the content of vitamin C for 120 days.

Key words: pH, titratable acidity, soluble solids, tropical fruit.

En este estudio, el efecto del procesamiento y el tiempo de almacenamiento en el contenido de vitamina C y licopeno fueron evaluados. Las guayabas fueron lavadas, cortadas en cuartos, escaldadas, despulpadas y la pulpa pasteurizada. La pulpa se utilizó en la producción del néctar: pulpa de guayaba, azúcar y agua se mezclaron en la proporción de 5:3:12, y la mezcla se pasteurizo, vertido en caliente en frascos de vidrio 125 ml, y se enfrío rápidamente a 25°C. La producción de néctar de guayaba fresca reduce la vitamina C, licopeno y la acidez titulable, en contraste los sólidos solubles y el pH se incrementan significativamente. El contenido de vitamina C de 168,9 a 62,3 mg/100 g de peso fresco, y el contenido de licopeno de 3,55 a 1,35 mg/100 de peso fresco (p < 0,001 en ambos casos). Después de 240 días a 10,0 ± 2ºC no se observó cambios estadísticamente significativos en el contenido del licopeno (p > 0,05). El tiempo de almacenamiento afectó el contenido de vitamina C, el pH y acidez titulable, el contenido de vitamina C se redujo en un 89,3% a 6,67 mg/100 g de peso fresco (p < 0,001). En base a este estudio, el almacenamiento de néctar de guayaba a 10°C, conserva el 46% del contenido de vitamina C durante 120 días

Palabras clave: pH, acidez titulable, sólidos solubles, fruta tropical.

Departamento de Ingeniería, Facultad de Ingeniería y Administración, Universidad Nacional de Colombia, Palmira, Valle del Cauca, Colombia

Guava (Psidium guajava L.) is an important fruit crop of subtropical and tropical regions (1). It is nutritionally important due to its high levels of vitamin C and pro-vitamin A (2); its vitamin C content is three to six times higher than that of orange, and its lycopene content twice that of tomato (3,4). There is evidence that increased intake of vitamin C and lycopene is associated with a reduced risk of chronic diseases such as cancer, cardiovascular disease and cataracts, probably through antioxidant mechanisms (5, 6).

Several guava products have been studied with regard to the influence of processing and storage time on their lycopene and vitamin C contents. Padula and Rodríguez-Amaya (7) reported lycopene losses of 17.6% and observed a 36% reduction in the vitamin C content of guava juice stored for 210 days at 4°C. Jawaheer et al. (8) reported a reduction of 70% in guava jam stored for 90 days at 25°C. Brunini et al. (9) reported vitamin C losses of 92% guava pulp stored for 154 days at -20°C. Other products have been evaluated: guava purée (10,11), sliced guava in syrup (10), and guava that had been dried by various methods (3,12,13). However, there has been no comprehensive investigation of the stability of these micronutrients in guava nectar during processing and storage. The findings reported here fill this gap in our knowledge.

A 24 kg sample of guava (Psidium guajava L. ‘Pera’) was purchased in Palmira (Colombia), and divided into six lots, which were processed in Laboratory Technology of Fruit and Vegetables of the National University of Colombia in accordance with standard industry practices. The guavas were washed with tapwater, and a portion of each lot was homogenized and analysed as described in Physicochemical analyses. The remaining fruits of each lot were disinfected by 5 minutes’ immersion in a 50 ppm solution of sodium hypochlorite, cut in quarters, blanched for 6 minutes in saturated steam at 97°C, and pulped mechanically on a 2 mm mesh sieve. Part of the pulp of each lot was pasteurized by a 30-minute treatment at 90°C and atmospheric pressure in a jacketed vessel, after which it was allowed to cool, packed in bags made of high density polyethylene 2 mm thick, and stored at 20°C pending analysis on the following day. The rest of the pulp was used for the production of nectar in compliance with Colombian regulation NTC 5468 (14): guava pulp, sugar and water were mixed in 5:3:12 proportions, and the mixture was pasteurized as above, poured while hot into 125 mL glass jars (leaving a 0.5 cm headspace), and cooled rapidly to 25°C by water jets. The jars of pasteurized nectar were stored 10.0 ± 2 ºC for up to 240 days. On days 0, 60, 120, 180 and 240, six jars were randomly selected (one from each lot) and were removed for analysis.

Titratable acidity (TA), pH and total soluble solids content (SS) were determined by official Colombian methods (15, 16 and 17, respectively); TA was expressed as (g citric acid)/(100 g fresh weight (fw)), and SS as °Brix. Lycopene was extracted as per Ordóñez-Santos et al. (18). Briefly, 2 g of the sample was weighed in a 250 mL Erlenmeyer flask, and 50 mL of 2:1:1 hexane/acetone/ethanol. The flask was covered with aluminium foil, and the flask was then placed in crushed ice and shaken for 10 min, after which 10 mL of distilled water was added and shaking was continued for a further 5 min. A 4 mL sample of the organic (hexane) phase was then taken with a Pasteur pipette and was quantified as mg/(100 g fw) as per Fish et al. (19), by measurement of the absorbance of the extract at 503 nm against hexane in a Genesys 10 UV-Vis spectrophotometer (Thermo Electron Scientific Instruments LLC, Madison, WI, USA).

Vitamin C was determined as per Oboh (20). Briefly, 5 g of the sample was extracted by 100 ml H2O and 10 ml of the extract was mixed with 25 ml of 20% glacial acetic acid and titrated against standardized 2,6-dichloroindophenol (0.05 g/100 ml) solution. Ascorbic acid was used as standard, and the result was expressed as mg/(100 g fw). All analyses were performed in triplicate.

Results are expressed as means ± standard deviations. The experimental data conform to one-factor complete randomized blocks designs with six replicates, and were analysed by one-way ANOVAs using fixed effects models and post hoc Tukey tests. All analyses were performed using SPSS for Windows v.17.

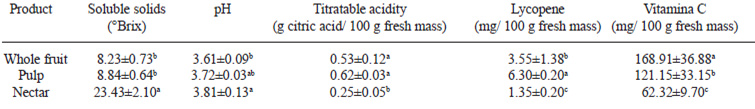

Table 1 lists the lycopene and vitamin C contents, and SS, pH and TA values, of homogenized whole guava, pulp and nectar on day 0. The SS, pH and TA of guava pulp did not differ significantly from those of the whole fruit, by contrast, pulping significantly increased lycopene content by 77.5% and Vitamin C content was significantly reduced by 28.3%. The transformation of pulp into nectar naturally increased SS (because of the added sugar), and consequently reduced TA and increased pH. Also, lycopene content was reduced to 38% of that of the whole fruit, and vitamin C content was further reduced to 37% of that of the whole fruit. The reduction of these two antioxidant effect is mainly due to the dilution and the nectar is only 25% of guava pulp.

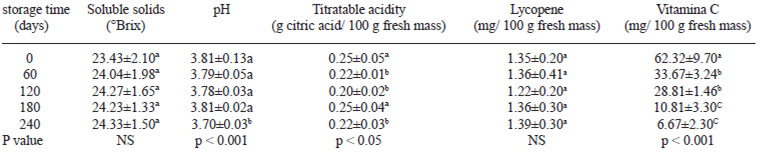

Storage for 240 days at 10.0 ± 2 ºC had no significant effect on either SS or lycopene content (Table 2). Storage time did affect pH, TA and vitamin C content. The pH was significantly lower on day 240 than at earlier times (3.70 as against 3.78-3.81). Compared with day 0, TA was significantly lower on days 60, 120 and 240 (in spite of the fall in pH), but not on day 180. Vitamin C content fell progressively throughout the study, especially between days 0 and 60 and between days 120 and 180; at the end of the study it was only 11% of its initial value.

The whole guavas had SS, pH and TA values similar to those reported by Brunini et al. (9) and Dos Reis et al. (21), average vitamin C levels almost exactly the same as the 168.5 mg/(100 g fw) observed by Vila et al. (22) but higher than the 67.9 mg/(100 g fw) of Brunini et al. (9), and lycopene contents lower than the 4.7-5.3 and 5.3-8.3 mg/(100 g fw) reported by Rodríguez-Amaya (23) and Rodríguez-Amaya et al. (24), respectively. Hypothesis of possible increase of lycopene during the pulping of the guava fruit, is the increase in free lycopene at the expense of protein-bound lycopene, because it may be partly due to the disruption of cell membranes by homogenization and heat treatment leading to the cleavage of protein-carotenoid complexes and hence to increased extractability of carotenoids (25). However, heat treatment might stimulate the transformation of some carotenoids into lycopene. Phytoene undergoes a series of desaturation reactions, each of which creates a new double bond and extends the chromophore by two conjugated double bonds; the end product is lycopene, produced via the intermediates phytofluene, ζ-carotene and neurosporene (26). The loss of vitamin C in the pulping of the guava fruit is greater than the loss of 11% (7) and 20.4% (8) that have been observed during the production of guava juice. These losses of vitamin C are probably due mainly to oxidation; in particular, the oxidation of vitamin C to dehydroascorbic acid is followed by hydrolysis of the latter to 2,3-diketogulonic acid, which then undergoes polymerization to other nutritionally inactive products (27). In this study, the reduction of lycopene and vitamin C in guava nectar is attributed mainly to the dilution effect generated by addition of water in the product and that the formulation of the nectar in took a 60% water.

The erratic changes of pH and acidity in this work may have been due to the combined effects of leaching and oxidation of organic acids in the biological matrix. Erratic changes of pH and acidity were reported by Brunini et al. (9) in guava pulp stored for 154 days at -20°C, and Freitas et al. (28) in acerola juice stored for 350 days at 28°C and. The stability of the lycopene during storage in this study, contrasts with reported lycopene losses of 17.6% during the storage of guava juice (7). The difference may have been due partly to the use of different pulping mesh sizes (2 mm in this study, 0.8-1.5 mm in the one of other authors (7), which may have led to different total solids contents; and partly to the stability of lycopene in the present study having possibly been favoured both by the thermal inactivation of enzymes that expose it to oxidants by destroying the cell wall (29), and by the presence of other antioxidants, including ascorbic acid, tocopherol, β-carotene, and phenolics (30).

The results of the loss of vitamin C during storage of guava nectar are consistent with other studies, Padula and Rodríguez-Amaya (7) observed a 36% reduction in the vitamin C content of guava juice stored for 210 days at 4°C, Jawaheer et al. (8) a reduction of 70% in guava jam stored for 90 days at 25°C, and Silva et al. (31) observed a 35% reduction in the vitamin C content of guava juice stored for 250 days at 28°C. The massive reduction observed in nectar of guava in the present study is attributable to the presence of free oxygen in the nectar jar headspace and to residual oxygen in the nectar, both of which will have contributed to the oxidation processes described by Dewanto et al. (27).

In conclusion, in this study, guava nectar obtained in accordance with official Colombian procedures has significantly greater pH and soluble solids content, and significantly less titratable acidity, lycopene and vitamin C, than the freshly homogenized whole fruit. Storage at 10.0 ± 2 ºC for 240 days has no statistically significant effect on soluble solids and lycopene contents, but slightly reduces pH following day 180, reduces vitamin C content to about 11% of its initial value, and causes small erratic changes in titratable acidity.

This work was financially supported by the Research Directorate of the National University of Colombia at Palmira (DIPAL).

Recibido: 09-07-2010

Aceptado: 26-09-2010