The aim of this study was to determine the optimal temperature ranges of milk fermentation by the microbial association Tibetan Kefir Grains and to set changes during the storage of the fermented milk product. The optimum technological parameters of milk fermentation by Tibetan Kefir Grains compliance are set. Compliance of these parameters ensures the desired metabolic processes and obtaining a dairy product with good organoleptic properties: fermentation temperature is 28±1 °С for 24 hours, acidity of the product is from 80 to 120 % lactic acid, the amount of lactic acid bacteria – (2.9±0.22) × 108 CFU/cm3, fungi – (3.7±0.27) × 104 CFU/cm3. It was found that during the storage of the fermented milk drink produced on the leaven Tibetan Kefir Grains at the temperature of 4 ± 1 °С for 10 days titratable acidity of the product increased by 1.2 times to 108.4 ± 8.3 °Т, the population of lactic acid bacteria (Lactobacillus fermentum and some other) and yeast (Saccharomyces spp and some other) remained at the initial level. This indicates that the finished fermented milk product can be stored without losing functional probiotic properties for at least 10 days and meets the requirements of the standard (ISO 4471). At the same time, at a temperature of +8 ± 1°С the expiration date of the fermented milk drink is decreases to 7 days.

Key words: Tibetan Kefir Starter, fermented milk drink, lactic acid microorganisms.

El objetivo de este estudio fue determinar los rangos de tempera- tura óptimos de la fermentación de la leche mediante la asociación microbiana de granos de Kéfir Tibetanos y estudiar los cambios durante el almacenamiento del producto lácteo fermentado. Se es- tablecieron los parámetros tecnológicos óptimos de fermentación de la leche utilizando los granos de Kéfir Tibetano. El cumplimien- to de estos parámetros garantiza los procesos metabólicos desea- dos y la obtención de un producto lácteo con buenas propiedades organolépticas: la temperatura de fermentación es de 28 ± 1° С durante 24 horas, la acidez del producto es de 80 a 120% de ácido láctico, la cantidad de bacterias del ácido láctico - (2.9 ± 0.22) × 108 UFC /cm3, hongos - (3.7 ± 0.27) × 104 UFC /cm3. Se encontró que durante el almacenamiento de la bebida láctea fermentada pro- ducida con los granos de Kéfir Tibetanos de levadura a una tempe- ratura de 4 ± 1° С durante 10 días, la acidez titulable del producto aumentó 1.2 veces a 108.4 ± 8.3 ° Т, la población de las bacterias del ácido láctico (Lactobacillus fermentum y algunas otras) y la levadura (Saccharomyces spp y otras) se mantuvieron en el nivel inicial. Esto indica que el producto lácteo fermentado terminado se puede almacenar sin perder propiedades probióticas funcionales durante al menos 10 días y cumple con los requisitos de la norma ISO 4417. Al mismo tiempo, a una temperatura de + 8 ± 1 ° С, la fecha de vencimiento de la bebida de leche fermentada se reduce a 7 días.

Palabras clave: Iniciador de Kéfir Tibetano, bebida de leche fermentada, microorganismos de ácido láctico.

https://www.doi.org/10.37527/2018.68.4.007

Fermented milk products are a palatable and economical source of a wide range of nutrients: protein, vitamins and minerals. The nutrient composition is similar to the one that milk has, but concentrations of vitamins are in general a little lower. However, in addition to these purely nutritional properties, there is increasing support for a number of other health advantages (1).

Among the large range of the fermented milk products, products that are based on the use of physiologically active natural symbiotic microbiota, deserve special attention. Production of these products is based on improving processes. It includes two points: first one is using traditional dairy strains of lactic acid bacteria, the second one is developing new fermented milk products with new types of microorganisms that show a probiotic properties (2-3).

Kefir is a specific dairy product from the group of fermented milks where lactose hydrolysis occurs during fermentation with the simultaneous action of bacteria (Lactobacillus acidophilus, Bifidobacterium bifidum, Streptococcus thermophilus, Lactobacillus delbrueckii subsp. bulgaricus, Lactobacillus helveticus, Lactobacillus kefiranofaciens, Lactococcus lactis, and Leuconostoc species) and yeasts (Kluyveromyces marxianus, Kluyveromyces lactis, Saccharomyces fragilis, Saccharomyces cerevisiae, Torulaspora delbrueckii, and Kazachstania unispora) contained in kefir grains (4-5). Kefir is traditional fermented milk product which has been produced and consumed for thousand years in the areas from Eastern Europe to Mongolia. It is believed that the name kefir derives from the mountain areas of Caucasus. Kefir grains represent a unique ecosystem in nature, formed by a symbiotic relation between bacteria and yeasts. A complex microbial community of kefir grains contains more than 50 various species of bacteria and yeasts and, depending on their origin, several species of filamentous moulds (6-7).

The microbial community of Tibetan kefir grains depends primarily on their source. It has been reported that Tibetan kefir grains contain Lactobacilli, Lactococci and yeast, and sometimes acetic acid bacteria, depending on the source of origin. As a naturally-existing yogurt starter, Tibetan kefir grains have some unique benefits and have attracted increasing attentions (8-12).

In recent years worldwide interest in the study of natural microbial associations such as “Tibetan or Indian fungi”, “Indian rice”, “Sea rice” is increased (13-15). Due to the wide range of biological active substances that are part of beverages, the relative simplicity of cultivation and the possibility of keeping culture for a long time in an active state these natural associations gained widespread in everyday life. Thus, in Belarus, polyculture of the microorganisms – the rice fungi Oryzamyces indici was intensively studied. Also biotechnology for the production of fermentation of soft drinks using fungi was offered (16-17). Natural association of microorganisms “Tibetan Kefir Grains” (local Ukrainian name Tibetan fungi) is widely used in home conditions to prepare fermented milk drink that from the perspective of traditional medicine is one of the leading places in activity effects on the human body (13-15).

Our research has found that the fermented milk drink made on the basis of the starter “Tibetan Kefir Grains” has a high antagonistic activity over the fungi of the genus Aspergillus and bacteria of the species Proteus vulgaris, sensitive to the Bacillus cereus, Mycobacterium luteum і Staphylocoсcus aureus.

Also, the microorganism of fermented product had resistance to the bad conditions of gastrointestinal tract, those were- the content of sodium chloride up to 4.0%, the content of bile – up to 20%, the concentration of phenol – up to 0.5% in favorable environment. The obtained data indicate that the fermented milk product belongs to the functional purpose.

The expiration date of the finished product without significant changes in organoleptic, microbiological and physic-chemical properties is important for the industrial use of the microbial association “Tibetan Kefir Grains”. Therefore, one of the main technological aspects that often limit the possibility of introducing a new product into production is a short expiration date. Given the above, the study of the influence of different temperatures on the microbiological and physico-chemical parameters of the finished fermented milk drink during its storage will allow to substantiate the expiration date of the product under production conditions.

The acceptable shelf life of a product is determined by the time it starts to loose its basic sensorial qualities. During storage, a product may become unpalatable in sense of toxicity by contamination with harmful microorganisms. It has been shown that the presence of pathogenic microorganisms in dairy foods is not correlated with microbial spoilage causing sensorial changes in products (18).

Thus, the industrial use of starter “Tibetan Kefir Grains” will expand the range of fermented milk products with a number of useful properties. Motivated by the strong progress in technology of the probiotic fermented milk product (19-21) in this work we determined the optimal temperature regimes for milk fermentation by the microbial association “Tibetan Kefir Grains” and set changes in the process of storing the fermented milk product.

The following mediums were used to isolate axenic cultures of microorganisms that are part of the microbial association “Tibetan Kefir Grains”. The medium of MRS-agar was used for isolation of axenic culture of lactic acid bacteria at 37±1 °С during 24-48 hours. The Sabouraud medium and beer wort medium were used for isolation of yeast at 25±1 °С during 3-5 days. Also beer wort with the addition of 3% ethanol and 0.5% CaCO3 was used for the selection of acetic acid bacteria at 37±1 °С during 24-48 hours. For determination of genus of selected strains bacteria and yeast were described using morphological and biochemical analysis. Morphology of isolated cultures of microorganisms was studied using a light microscope Trinocular MBL2100 (“Krus”, Germany) at eyepiece 20 and lens 100. The final identification of strains of lactic acid bacteria to specie was carried out by a range of carbohydrates fermentation tests (API 50SN - Bio Merieux, Inc, France) used according to the manufacturer’s recommendations. Also species belonging of isolated cultures of lactic acid microorganisms was studied using PCR (polymerase chain reaction). PCR was also used to identify lactic acid microflora, PCR protocols were carried out according to previous works (22-23). As primer was used 16S rDNA sequence (24).

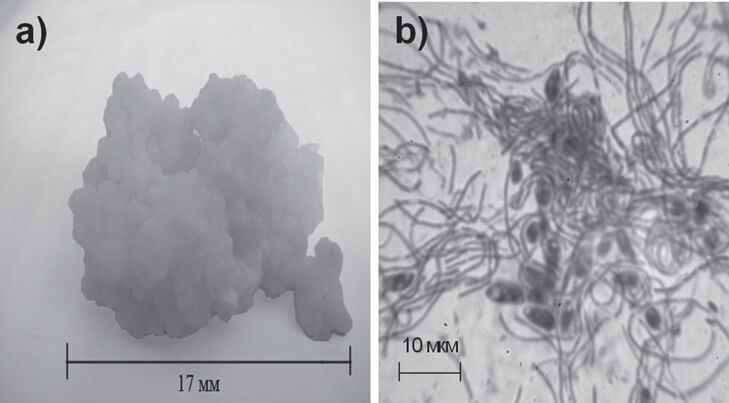

Previous studies (13-15) found that the “Tibetan Kefir Grains” is a white lump, without a specific odor, size from 3-6 mm (young fungus) to 3-5 cm in diameter (fungus before separation) (Figure 1a,b).

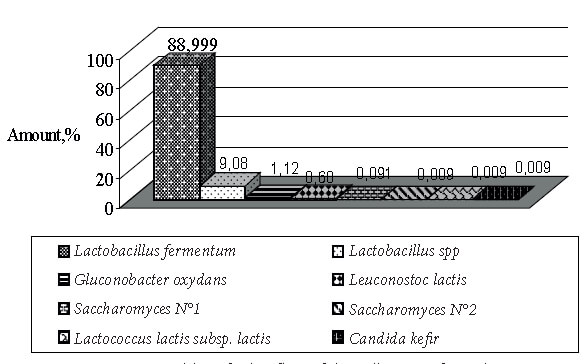

The morphology of the microorganisms present in the starter “Tibetan Kefir Grains” found (Figure 1b) existence of oval and long-form yeast cells which are surrounded by cocci and single and chain rod-shaped bacteria. Microbiological studies using classical methods and PCR-identification methods (Figure 2) found that the association studied consists of two types of yeast and four types of bacterial cells.

Lactobacillus fermentum are much dominated among all microorganisms, accounting for 88.99% of the total number of the cells of a lump fungus weighing 1 g.

The bacterial cells of the genus Lactobacillus spp. are found on the second place, their account for an average of 9%. Still about 1.12% in the starter accounts for bacteria genus Gluconobacter oxydans and 0.68% for Leuconostoc lactis. The total amount of the fungi was nearly 0.1%.

The correlation of yeast and lactobacillus in the culture liquid of the fermented milk product is important for the probiotic properties of the beverage. In order to receive the fermented milk product, we need to add 2.5-5% of the seed material from the association of microorganisms “Tibetan Kefir Grains”, it will make the cow’s milk sterile which contains a mass fraction of fat 2.5% and cultivation to the value of the acidity of the medium 85 – 120 °Т.

It is known that functional properties of finished product depend on quantitative correlation of probiotic microorganisms in it. In most cases lactobacilli have a positive impact on human health because of their increased level may indicate the potential probiotic properties of the beverage. We observed intensive multiplication of yeast cells, whose number was (5.9±0.42)×105, and complete inhibition of lactobacilli at the fermentation temperature of 22 °С during 48 hours. Fermentation of milk at a temperature of 28 °С caused the multiplication of all associated microbial of “Tibetan Kefir Grains”. As a result, the number of yeast cells was (3.7±0.27) ×104 and lactobacilli cells − (2.9±0.22) ×108 after 24 hours of cultivation. This proportion of these groups of microorganisms in the fermented milk product − such as kefir meets the requirements of the normative document ISO 4417:2005. Kefir. Specifications (25). However, the maximum number of lactobacilli cells (5.7±0.30) ×108 was achieved at the fermentation temperature of milk 35 °С for 5 hours. At the same time the number of yeast cells in such fermented milk drink was (5.2±0.31) ×102 that does not comply with the standard.

Consequently, the results indicate that for optimal quantitative accumulation of yeasts and lactobacilli in the fermented milk product, produced with using the leaven “Tibetan Kefir Grains” favorable temperature for fermentation of milk was 28 ± 1°С.

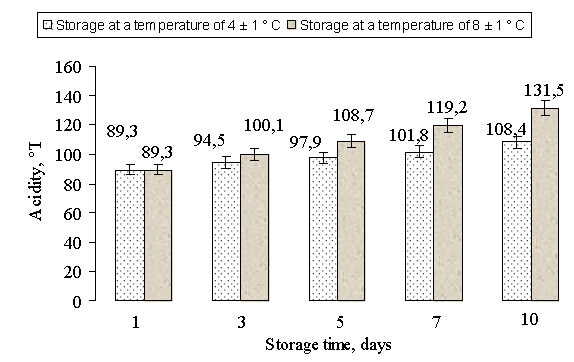

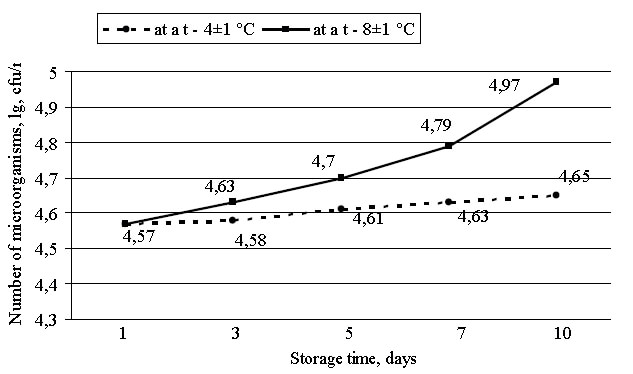

The study of the effect of the expiration date of the fermented milk product at different temperatures for 10 days is given in Figure 3.

Revealed, that storage of the resulting fermented milk product at a temperature of +4±1 °С for 10 days detected a slight increase its total acidity. So, acidity increased in 1.9 times (from 89.3±7.7 °Т to 97.9±7.4 °Т) during five days of storage, after 10 days the acidity increased in 1.2 times to 108.4±8.3 °Т. There is a more intense increase in acidity in the fermented milk drink during storage at +8±1 °С. The titrated acidity increased in 1.3 times for five days, and after 10 days from the beginning of the experiment, it exceeded the permissible quantity, which is normalized with ISO 4417: 2005 (25).

Thus, the fermented sour-milk product at the microbial association “Tibetan Kefir Grains”, at a temperature of +4 ± 1°С, can be stored without changes of organoleptic and physical-chemical properties for at least 10 days, at the same time at a temperature of +8 ± 1ºС the expiration date is reduced to 7 days.

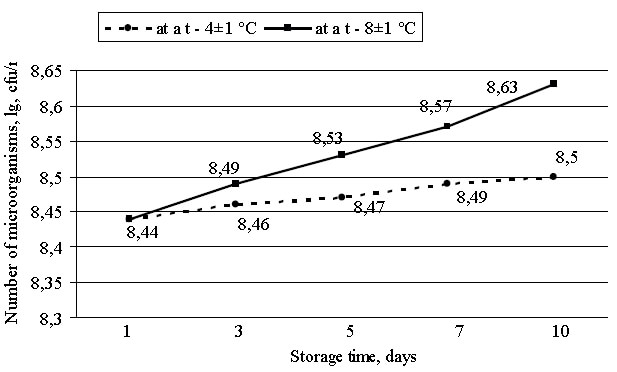

In Figure 4 and Figure 5 the results of investigations of changes in the population of lactic bacteria and yeast in the sour-milk drinks fermented on the starter “Tibetan Kefir Grains” at different storage temperatures are given.

Revealed, that ten-day holding of the fermented milk product at a temperature of +4 ± 1°С didn’t significantly affect on the number of lactic acid bacteria. The amount of lactobacilli practically remained on the original content, this indicates that the finished fermented milk product, which is made on the leaven “Tibetan Kefir Grains” can be stored without losing functional probiotic properties, not less than 10 days and meets the requirements of the ISO. Storage at a temperature of +8 ± 1°С contributed to the development of lactic microbiota, which gradually increased, especially the microbiological process intensified after 7 days of storage.

In the study of the content of yeast in the fermented milk drinks at different storage temperatures, practically similar regularities of development, as well as lactic acid bacteria were found. The amount of yeast increased insignificantly at +4 ± 1°С for 10 days, and intensively increased at +8 ± 1°С from the fifth day of storage. The rapid development of yeast in the fermented milk product produces off flavours its organoleptic properties.

In conducting the organoleptic assessment of the quality of the resulting product, the following indices were investigated: consistency and appearance, taste and smell, color.

Revealed, that the resulting drink based on the leaven “Tibetan Kefir Grains”, which was stored at +4±1 °С for 10 days, according to the organoleptic properties meets the requirements for fermented milk drinks:

At the same time, the drink which was keeping at a temperature of +8±1 °С since the fifth day had a sharp taste and significant gas formation.

Therefore, using the microbial association “Tibetan Kefir Grains” can be the basis for obtaining the fermented milk drink, which should be stored at a temperature above +4± 1 °С and not longer than 10 days.

The optimum technological parameters of milk fermentation by “Tibetan Kefir Grains” were successfully determined. Compliance of these parameters ensures the desired metabolic processes and obtaining the fermented milk product with good organoleptic properties: fermentation temperature is 28±1 °С for 24 hours, acidity of the product is from 80 to 120 °Т, the amount of lactic acid bacteria – (2.9±0.22) × 108 CFU/cm3, fungi – (3.7±0.27) × 104 CFU/cm3.

During the storage of the fermented milk product produced on the leaven “Tibetan Kefir Grains” at 4±1 °С for 10 days titrated acidity of the product increased in 1.2 times to 108.4±8.3 °Т, the content of lactic acid microorganisms (lactobacilli and yeast) remained at the initial level. This indicates that the finished fermented milk product can be stored without losing functional probiotic properties for at least 10 days and meets the requirements of the standard.

There are no conflicts to declare.

Recibido: 29-01-2019

Aceptado: 20-05-2019