Bárbara Pereira da Silva2,

Bárbara Pereira da Silva2,  Maria Inês de Souza Dantas1,

Maria Inês de Souza Dantas1,  Fátima Ladeira Mendes Duarte1,

Fátima Ladeira Mendes Duarte1,  Hercia Stampini Duarte Martino1,

Hercia Stampini Duarte Martino1,  Mirella Lima Binoti1

Mirella Lima Binoti1

The objective of this work was to develop cookies using sorghum, germinated millet and chia flours. Four formulations (F) were used: F-sorghum (100% sorghum flour); F-Sorghum + chia (50% sorghum flour and 50% chia flour), F-millet (100% millet flour) and F-millet + chia (50% millet flour and 50% chia flour). The germinated millet flour was submitted to microbiological analysis. All cookies were evaluated in relation to chemical and sensory analyses, according to AOAC and hedonic nine-point scale, respectively. The statistical analysis was performed by the variance analysis and Tukey test at 5% probability. The F-millet formulation showed the least humidity content (4.59 ± 0.25g/100g), while chia containing cookies showed lesser concentrations of carbohydrates (F-sorghum + chia: 44.35 ± 4.34g/100g and F-millet + chia: 41.03 ± 1.40g/100g) and higher ash content (F-sorghum + chia: 3.80 ± 0.02g/100g and F-millet + chia: 3.42 ± 0.24g/100g) and of protein (F-sorghum + chia: 15.38 ± 0.44 g/100g and F-millet + chia: 18.06 ± 0.53 g/100g). The caloric value and the lipids content did not differ among formulations. The sensory analysis had 57 evaluators. The cookies produced with chia and germinated millet had higher rates for flavor, texture and general impression. In general, all tested biscuits had good sensory acceptance and nutritional quality being an alternative to increase the consumption of bioactive compounds and antioxidants. Arch Latinoam Nutr 2021; 71(3): 218-227.

Keywords: dietary fiber, health benefit, gluten free diet, nutritional value, sensorial analysis.

El objetivo fue desarrollar galletas utilizando harina de sorgo, mijo germinado y chía. Se utilizaron cuatro formulaciones (F): F-sorgo (100% harina de sorgo); Sorgo F + chía (50% harina de sorgo y 50% harina de chía), mijo F (100% harina de mijo) y mijo F + chía (50% harina de mijo y 50% harina de chía). La harina de mijo germinada se sometió a análisis microbiológico. Las galletas fueron sometidas a análisis químico y sensorial, según la AOAC y una escala hedónica de nueve puntos, respectivamente. El análisis estadístico se realizó mediante análisis de varianza y prueba de Tukey al 5% de probabilidad. La formulación F-mijo tuvo menor contenido de humedad (4,59 ± 0,25 g/100g), mientras que las galletas que contenían chía tuvieron concentraciones más bajas de carbohidratos (F-sorgo + chía: 44,35 ± 4,34 g/100g y F-mijo + chía: 41,03 ± 1,40 g / 100g), mayor contenido de cenizas (F-sorgo + chía: 3,80 ± 0,02 g/100g y F-mijo + chía: 3,42 ± 0,24 g/100g) y proteínas (F-sorgo + chía: 15,38 ± 0,44 g/100g y F mijo + chía: 18,06 ± 0,53 g/100g). El valor calórico y el contenido de lípidos no difirieron entre las formulaciones. El análisis sensorial contó con 57 evaluadores. Las galletas producidas con chía y mijo germinado tenían notas más altas de sabor, textura e impresión general. Las galletas testadas tuvieron buena aceptación sensorial y calidad nutricional, siendo una alternativa para incrementar el consumo de compuestos bioactivos y antioxidantes. Arch Latinoam Nutr 2021; 71(3): 218-227.

Palabras clave: fibra dietética, beneficio para la salud, dieta sin gluten, valor nutricional, análisis sensorial.

https://doi.org/10.37527/2021.71.3.006

Autor para la correspondencia: Mirella Lima Binoti, E-mail: [email protected]

Currently, consumers are looking for healthier foods, with advanced nutritive value and easy consumption. The demand for these attributes promotes the need to develop fast, practical and nutritionally balanced preparations, and furnishing health and food safety for individualities. Likewise, it can be increasingly perceived the presence of individualities with food allergies and intolerances, similar as celiac disease and lactose intolerance, being seductive the development of specific preparations for this public. Therefore, the usage of sorghum, millet and chia flours is interesting, since these foods present innumerable nutritive benefits, in addition to not having gluten in their composition (1, 2, 3).

Sorghum (Sorghum bicolor (L.) Moench), a cereal native from Africa, has high minerals composition, such as potassium and phosphorus; and vitamins, such as complex B and fat-soluble vitamins (1). The BRS 305 crop, that shows pigmented forehead, have a higher concentration of condensed tannins, being able to promote additional health benefits (1). Besides this, we can observe that sorghum present considerable content of phenolic compounds and flavonoids with potential benefit for human health. Because of sorghum’s composition, it can improve body antioxidant capacity and reduce the inflammation (1), and oxidative stress, in vivo (4). The benefic effect of sorghum on obesity and hepatic steatosis are due the presence of bioactive compounds, especially the proanthocyanins, phenolic acids and dietary fiber, which can reduce the caloric availability of ingested food, promote satiety, and can complexes to proteins and some carbohydrates, inhibiting the digestion and absorption of these components (5,6).

Millet (Pennisetum glaucum (L.) R Br.) is widely consumed in the semiarid regions, such as Africa and India. This cereal is a source of protein and dietary fiber (7). It also contains minerals and bioactive compounds (2) found mainly in the grain pericarp, and therefore it is recommended its whole consumption.

Chia (Salvia hispanica L.) has a chemical composition and nutritional value that varies according to the species, climactic condition, place of farming and kind of soil in which it is produced. The main components of the seed are lipids, being mostly composed of polyunsaturated fatty acids such as α-linolenic and linoleic. Moreover, chia seeds are rich in dietary fibers, despite it also standing out in proteins and bioactive compounds, such as phenolics, carotenoids, minerals and vitamins (3). It is important to highlight that defatted chia flour presents hydroxycinnamic acids, such as salviaflaside and rosmarinic acid, which are polyphenols (8). Due to the presence of these compounds, the benefits from the consumption of this food are uncountable. Consumption of chia is capable to reducing oxidative stress, increase the antioxidizing capacity, improve the glucose metabolism and the lipid profile, when combined to the consumption of lipid rich diets, in animal and human models (9).

Therefore, this product is an option that has great public acceptance, it is practical to be consumed and still presents prolonged shelf life (10). Besides this, innovation of this study is based on the fact that we use, in combination, three different types of flour with beneficial effects to the body to produce a cookie, which has not yet been highlighted in the literature. Thus, this study aimed to develop cookies using as main ingredients sorghum, germinated milled and chia flours.

Conventional sorghum seeds (BR 305 genotype) and germinated millet were provided by the Brazilian Agricultural Research Corporation (Embrapa) Food Agroindustry (RJ, Brazil). Chia seeds were acquired in Rio Grande do Sul state (RS, Brazil). The remaining ingredients (brown sugar [Nayna®], eggs, extra virgin olive oil [Cocinero®], vanilla essence [Fleischmann®], cinnamon [Kitano®], baking powder [Royal®] and salt [Globo®]) were acquired in local market.

It was used the grains of BRS 305 genotype to get whole sorghum flour. The seeds were thermally treated using a heating chamber with forced air circulation (Nova Ética®, model 400 ND, São Paulo, Brazil) at 125ºC, for 25 minutes. Next, they were milled in an analytical micromotor (850 mm) (Marconi®, model MA 090/CFT, Piracicaba, São Paulo, Brazil) and sieved with a 40-mesh sieve (10), obtaining the flour, which was packaged in polyethylene bags and stored at -18ºC.

For the millet flour, at first the whole seeds were germinated. The seeds were soaked in water (1/3 ratio: seed/water) for 3 hours, germinated at (30 ± 2ºC) temperature and controlled relative moisture (90%). After 24 hours of germination, the seeds were dried in a DMS-G-EG model oven (Macaduna Hauber, Joinville, Brazil) at 50ºC for 4 hours, until the final moisture be inferior to 7%, and after that they were milled.

Chia seeds were sent to the Department of Nutrition and Health of Federal University of Viçosa after their harvest. Chia flour was obtained by grinding in a blender (Philips Walita). After this process, the flour was defatted by cold pressing, using hydraulic press. After, the defatted chia flour was stored at -18ºC until the moment of use.

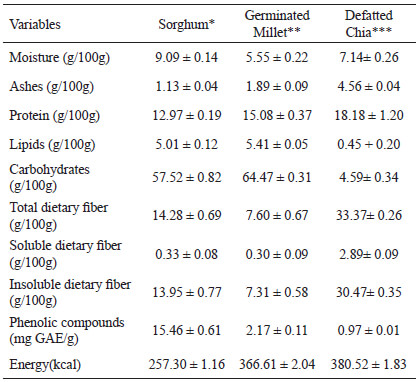

The chemical characterization of the whole sorghum genotype BRS 305, germinated millet and chia flours were determined previously by the researchers of the Experimental Nutrition laboratory of the Federal University of Viçosa (11, 12, 3). The measurement of moisture was performed by the drying method in a heating chamber for 24 hours at 105ºC (AOAC Official Method 950.46); the concentration of proteins through the Kjeldahl method (AOAC Official Method 945.18); the lipids content by direct extraction in Soxhlet (AOAC Official Method 923.05); the concentration of ashes, in a muffle furnace for 18 hours at 300ºC to 600ºC (AOAC Official Method 920.153). The carbohydrates content was calculated by the difference (13). The determination of total fiber and soluble and insoluble fractions was performed by the enzymatic-gravimetric method, using the enzymatic hydrolysis for a heat-resistant amylase, protease and amylglucosidase (total dietary fiber assay Kiyonaga, Sigma®, Kawasaki, Japan). The total phenolic compounds content in chia were determined using the Folin-Ciocalteu method (14). The reading of absorbance was performed in spectrophotometer (Thermo scientific, Evolution 606, USA) at 765 nm. Analytical curve of gallic acid (0,005–0,10 mg/mL) was used to quantify the compounds. The results were expressed in mg of gallic acid equivalents/g of chia flour (mg GAE/g). The composition of these flours is available on Table 1.

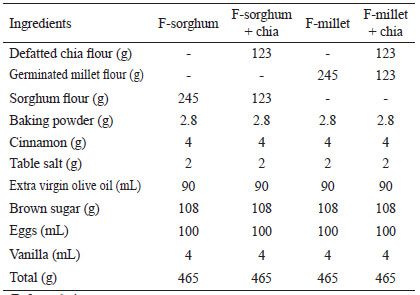

The cookies were developed based in a standard formulation already tested and sensory assessed on the Laboratory of Sensory Analysis and Development of New Products of the Department of Nutrition and Health of Federal University of Viçosa (15). The concentration of whole sorghum, germinated millet and chia flours were set through tests performed from August 2018 to May 2019 and were chosen due to the nutritional and sensory characteristics that added to the product. Therefore, it was established 4 formulations (Table 2). The average recipe yield was 50 units and each biscuit presented is an average of 8g with approximately 35 mm.

For the making of the cookies, at first, the flours, baking powder, cinnamon and salt were sieved. Alongside, the eggs, vanilla, olive oil and brown sugar were mixed in a bowl. In the same vessel, the previously mixed dry ingredients were added, continuously mixed until complete homogenization.

The cookies were shaped in a circular manner, arranged in a tray lined with baking paper and baked in a domestic oven (Diplomata Grill®) at 200ºC for 15 minutes. After cooking they were cooled in 22°C temperature for 2 hours and packaged in high density polyethylene bags. Before being analyzed, the cookies were stored under freezing temperature (-18°C).

The cookies chemical composition analysis was performed according to Association of Official Analytical Chemistry (AOAC) (2018) (13). Each analysis was held in three repetitions, for each formulation. The measurement of moisture was performed by the drying method in a heating chamber for 24 hours at 105 ºC (AOAC Official Method 950.46); the concentration of proteins through the Kjeldahl method (AOAC Official Method 945.18); the lipids content by direct extraction in Soxhlet (AOAC Official Method 923.05); the concentration of ashes, in a muffle furnace for 18 hours at 300 ºC to 600 ºC (AOAC Official Method 920.153). The carbohydrates content was calculated by the difference, that is, 100 minus the sum of the fractions of proteins, lipids, ashes and moisture. The total energetic value in 100 g of each cookie formulation was established accordingly to the energy values estimated of the Atwater conversion. The sum of the products makes up the total energetic value (16).

To ensure the harmlessness of the germinated millet flour the microbiological analysis was performed (Salmonella ssp, Bacillus cereus, coli form, fungi and yeast) following the Identity and Quality Standards (PIQ) for flours, established by the Brazilian Health Regulatory Agency (ANVISA) (17). Salmonella ssp. determination was conducted using the presence/absence technique (qualitative determination; ISO 6579-1:2017). Bacillus cereus was quantified using quantitative determination by surface counting technique (ISO 7932-2004). The coli forms were quantified by quantitative determination using the in-depth counting technique (ISO 4832-2006). Finally, molds and yeasts were determined by surface counting technique (quantitative determination; ISO 21527-2:2008). The analysis was performed in the Laboratory of Analysis of Food Products (LAPA), of the Department of Food Technology of the Federal University of Viçosa.

The formulations were subjected to the acceptance test, using a structured hedonic scale of nine points (varying from “1 - disliked tremendously” to “9 - liked tremendously”) and were assessed the attributes flavor, texture (especially hardness and crunchy), aroma and general impression (18). Participants were selected based on frequency of cookie consumption and they were invited to attend randomly through posters fixed on the Department of Nutrition and Health, and promotions in social networks, such as Facebook and Instagram.

The tests were performed in laboratory conditions, in individual booths, under white light. The formulations were presented to the participants in a monadic way, using a complete randomize block design. Standardized portions were presented to the consumers in disposable white plates, codified with three-digit numbers. To each individual it was served a glass of water to wash the taste buds between the tastings of the samples (18). Previously to the sensory analysis, each participant signed an Informed Consent Form (TCLE). The project was approved by the research ethics committee on human beings of UFV (Opinion number 3.259.183).

Individuals from 17 to 60 years old were included as research participants, students or workers of Federal University of Viçosa, without gender or ethnic differentiation and which showed interest and availability to judge the product, in addition of being considered potential consumers. Individuals who were not potential consumers or that had any sensitivity to the formulation components, physiological or pathological limitations at the moment of analysis were excluded from the research.

The obtained results were tabbed in an Excel spreadsheet (Microsoft Office 2016©), subjected to variance analysis (ANOVA), followed by pos hoc and Tukey test with significance level of 5%, through the statistical program Open Epi, version 3.01.

The chemical composition of flours is shown on Table 1. The sorghum and the millet flour have high concentration of carbohydrate. Sorghum flour have low amount of lipids (5.01 ± 0.12g/100g), and high phenolic compounds (15.46 ± 0.61g/100g) content. In the same way, it is noted that chia flour has a good amount of protein (18.18 ± 1.20g/100g) and ash (4.56 ± 0.04 g/100g). In addition, we can note that total dietary fiber (33.37 ± 0.26 g/100g), including soluble and insoluble fiber, is very expressive on chia flour.

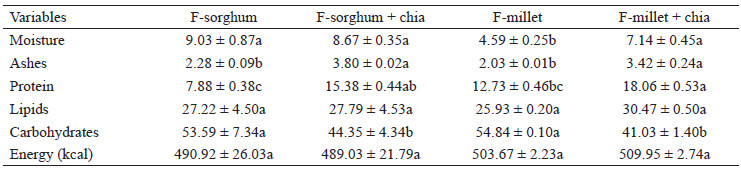

The content of moisture, ashes, protein, lipids, carbohydrates and energy is shown on Table 3. About the moisture, only the millet formulation (4.59 ± 0.25g/100g) distinguished itself from the others. The ashes content was higher in both chia samples (F-sorghum + chia: 3.80 ± 0.02 g/100g and F-millet + chia: 3.42 ± 0.24g/100g). As observed on the ashes content, the protein concentration was higher in chia formulations (F-sorghum + chia: 15.38 ± 0.44g/100g and F-millet + chia: 18.06 ± 0.53g/100g) compared with the sorghum flour formulation (7.88 ± 0.38g/100g). The lipid content did not statistically vary in absolute values between formulations. The carbohydrate content of chia formulations was lower compared with the other formulations (F-sorghum + chia: 44.35 ± 4.34 g/100 g and F-millet + chia: 41.03 ± 1.40 g/100 g) and the caloric value did not differ among formulations.

The results of microbiological analysis presented were performed on germinated milled flour. It is possible to observed the absence of Salmonella ssp and Bacillus cereus in the formulations. Coliforms 45ºC were observed in an amount inferior to 1x101 UFC/g, while fungi and yeast were measured as 9x102 UFC/g. This result is in according to the Quality Standards, which requires absence of Salmonella ssp. Besides this, Bacillus cereus and Coliforms 45ºC must be under 3x10³/g and 10² /g, respectively. Fungi and yeast must be under 103/g (14).

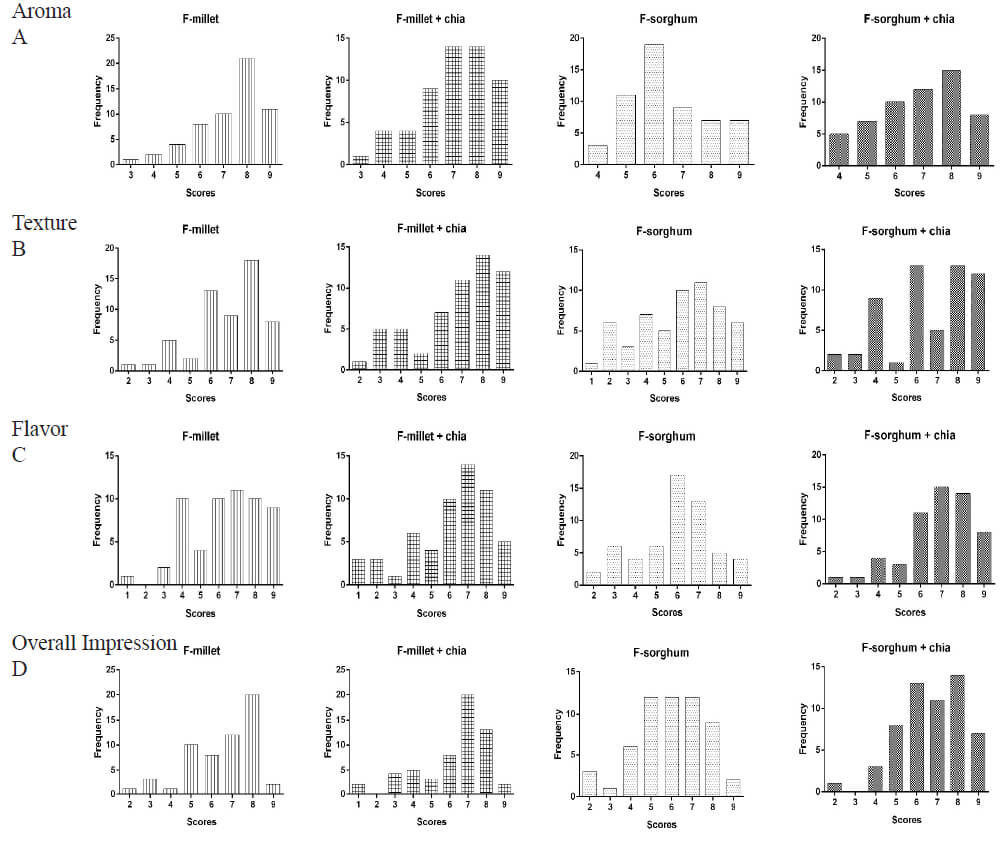

57 consumers participated in the sensory analysis, 30% of them being males (n=17) and 70% females (n=40), 18 to 70 years old. All samples were accepted, attaining scores at least of 6 for all assessed attributes, corresponding to the hedonic term “slightly liked” (Figure 1).

The addition of chia flour to sorghum flour in the cookies improved the scores concerning the texture sensory attributes (Figure 1B: 6.59 ± 2.03) and flavor (Figure 1C 6.85 ± 1.60) in relation to the preparation containing only sorghum flour (Figure 1B: 5.78 ± 2.21 and Figure 1C 5.91 ± 1.77, respectively) (p<0.05). In relation to these attributes, cookies produced using millet, regardless of chia presence, had higher (p<0.05) scores (texture: F-millet: 6.87 ± 1.66 and F-millet + chia: 6.77 ± 2.00; flavor: F-millet: 6.40 ± 1.93 and F-millet + chia: 6.08 ± 2.16) (Figure 1B and 1C) compared to cookies produced with sorghum flour.

In the aroma aspect, the formulation prepared with millet received higher scores (7.29 ± 1.45) compared with the preparation containing only sorghum flour (6.38 ± 1.57). However, chia addition did not interfere this variable (Figure 1A).

According to the general impression attribute, cookies prepared with sorghum + chia flour (6.73 ± 1.55) should best results (p<0.05) when compared with cookies prepared with sorghum flour (5.94 ± 1.68). In relation to the germinated millet flour formulation, the addition of chia flour did not alter the acceptability regarding aroma, texture, flavor and general impression (p<0.05) (Figure 1C).

The germinated millet alone produces lower moisture to the biscuit, however, after adding chia, there is an increase. Although chia has a predominance of insoluble fiber in its food matrix, the concentration of soluble fiber is high, which favors its great water absorption capability and form gel called mucilage. Similar result was found by Brandão et al. (19) in which was analyzed the moisture of cookies made with different types of chia flour. Despite this increment of moisture in the formulation containing millet combined with chia, the values observed are lower than the 14% established by Resolution-CNNPA nº 12, from 1978 for biscuits and wafers (17). Therefore, we can affirm that the cookie moisture is according to what is established by the manufacturing standards and the product shelf life will be possible to be extended, since the moisture is connected to physical changes in food structure (20).

The ashes content was higher in both chia samples. It can be explained due to the presence of some minerals such as magnesium, calcium, potassium and phosphorous, which constitute its food matrix (3). Therefore, it showed that chia flour contributed positively to the mineral content, like is shown on Goyat et al. (21) study where the replacement of 15% of wheat flour by chia flour was capable to increase calcium and iron content of the cookies. The protein concentration was higher in chia formulations compared with the whole sorghum flour formulation. This is due to the 18% protein content of chia flour (3) while sorghum presents a lower concentration of this macronutrient, making up around 12% of the seed composition (11). Other studies adding defatted chia flour to formulas had similar results (23,24).

Despite the cookie’s lipid content did not statistically vary in absolute values between formulations, it can broadly vary in comparison to its fatty acids. This alteration in the cookie’s composition depends on the kind of flour used. Among them, chia flour is highlighted as it is rich in omega-3 fatty acids (20.37 ± 1.38 g/100g) and omega-6 fatty acids (5.69 ± 0.42 g/100g) (3). It is worth mentioning that defatted chia flour was used, since this food presents a higher concentration of polyunsaturated fatty acids that can be easily oxidized and consequently influence the sensory analysis of the product. Although the chia flour was defatted, when pressure systems are used to extract oil, normally some of fat remains (mainly polyunsaturated fatty acids) in the defatted flour (24). Besides this, the thermic treatment used to produce chia cookies probably did not change the polyunsaturated fatty acid contents, since a study showed that this procedure has a minimal reduction on the polyunsaturated fatty acid fraction (25).

The carbohydrate content of chia formulations was lower compared with other formulations. This correlates to the lower content of this nutrient in chia seed, which is approximately 4% (3,19). So, defatted chia flour can be a good alternative to produce cookies since it has a high content of fiber and protein and low concentration of carbohydrate (24). The caloric value did not differ between formulations.

Furthermore, the consumption of cookies, especially formulations containing chia which were the most accepted, can be a great alternative to the supply of bioactive compounds to the organism, since these are found in used flours.

It is important highlight that the application of high temperature to the products (cookies) can influence on antioxidant and total phenolics substances, increasing these compounds (25). The effect was observed by Hatamian et al. (26). The authors noted that heat application to chia seed flour had beneficial results on functional properties and total phenolics content of the product (26). These compounds are related to the reduction of oxidative stress, chronic non-communicable diseases and the installation of the inflammatory process in the body (9). So, the use of different parameter in the binomial time and temperature can be investigated in further studies.

It is important to highlight that defatted chia was used, because in previous tests, using the whole grain, was noted that the chia oil leaves an aftertaste that is not palatable. In addition, to obtain a cookie attribute was needed a new source of lipid. Then, the olive oil was chosen by its nutritional value and nutritional benefits. Although the chia flour was defatted, part of the phenolic fraction was still preserved as well as shown in Mas et al.(8) study who have found that some polyphenols increased and others decreased after cooking, but almost all of them were recovered. This result can also indicate that the antioxidant capacity may change as well (27).

In relation to microbiological analysis of germinated millet flour, the samples were in according with the legal examined standards, that references the absence of Salmonella ssp and allows, at most, 3x103 UFC/g of Bacillus cereus and 102 UFC/g of coliforms 45ºC (28).The addition of chia flour (F-sorghum+chia and F-millet + chia) improved the texture and flavor sensory attributes in relation to sorghum formulation (F-sorghum).This upgrading on the texture might be explained by the adding of chia that decreases the hardness of the cookies due the higher dietary fiber content and the kind of fiber present in this food, which grants softness to the products (22). According to Jiang et al. (29), the fiber allows modification in the texture and stability of the products. The not favorable flavor result observed to sorghum flour can be due the chemical composition, since the grain presents phenolic compounds (1.10 ± 0.02 mg gallic acid/g sample) and condensed tannins (proanthocyanidins) (0.71 ± 0.08 catechin equivalent/g sample), which in very small quantities, are able to reduce the palatability by forming protein and carbohydrate complexes, promoting an astringent flavor to the formulation (30).

Martínez et al. (23) analyzed the texture of different biscuits manufactured with sorghum and bean flour. It was tested six formulations, being: control (wheat flour), 100% sorghum, 10% sorghum substitution, 30% sorghum substitution, 100% bean, 10% bean substitution and 30% bean substitution. The preparation containing only sorghum flour was the toughest and, consequently, the less accepted in relation to control.

According to Bi et al. (31), aroma is the main signaler of millet and millet-bearing foods quality. Furthermore, after thermal treatment, millet shows a flavor improvement, since some studies has shown that some compounds, such as phytic acid, presents on the flour can improve this attribute (32,33). Bi et al.(31) assessed the influence of millet (Setariaitalica) consumption on the sensory characteristics of food products and noticed that the volatile compounds present in the grain, such as aldehyde, pyrazine and hydrocarbon compounds, were capable of improving the flavor profile of manufactured products (31,34). Bi et al. (31) also associated the roasting with some volatile compounds, such as pyrazine (methylpyrazine, 2-ethyl-5-methylpyrazine, and 2-ethyl-3,5-dimethylpyrazine). The compounds confer a roasted and nutty odor description to the product, which occurs due to maillard reaction. Thus, the improvement on the germinated millet cookies’ aroma in the present study can be granted to the presence of volatile compounds in the food. About sorghum volatile compounds, some are lost by heating process (alcohol, ester, carboxylic acid and ketone) and some increase (alkane and aldehyde).Furthermore, other compounds are formed after heating process. Xiong et al.(35), compared raw sorghum flour with a roasted flour and found that pyrazines were detected after the roasting process. This volatile compound is formed by Maillard reactions and contributes with the roasted aroma.

In relation to cookies produced from millet, the addition of chia flour to germinated millet flour (F-millet + chia) did not alter the acceptability regarding aroma, texture, flavor and general impression (p<0.05) when compared to germinated millet flour (F-millet). The addition of chia in biscuit formulations is being studied and results show good acceptance, according to the values observed in relation to aroma and flavor. In Mas and collaborators(8) study, defatted chia flour was used for the development of sweet biscuits in a 0, 5, 10 and 20% concentration, in substitution to wheat flour. The biscuits had good acceptance and the most approved formulations were those of 10, 5 and 20%, being the last formulation of highest preference.

It is notable that in our study it was used a higher concentration of chia flour in the elaboration of the cookies (50%) in relation to existent studies, which have not interfered in the acceptance of products. It is still possible to observe that the studies used chia combined with other kinds of refined flours, such as wheat flour. Therefore, the differential of our study is based on the development of products manufactured only with sorghum, germinated millet and chia flours, being, consequently, gluten-free formulations.

In general, all cookies’ formulations showed good sensory acceptance. However, the sorghum flour formulation stood out in the flavor, texture and general impression when added with chia flour. Chia addition to cookies produced with germinated millet flour did not have influence on sensory attributes. Moreover, it can be observed that the addition of flours used in the study contributed to increase the nutritional value of the cookies, since they are source of bioactive and antioxidants compounds.

The authors thank Dr. Carlos Wanderly Piller de Carvalho (Embrapa Agroindústria de Alimentos, Brazil), Dra. Valéria Aparecida Vieira Queiroz (Embrapa – Maize and Sorghum, Brazil), and Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq, Brazil) for financial support.

We declare that there is no conflict of interest.

Recibido: 09/04/2021

Aceptado: 17/08/2021